The Caproni Ca.100 and Ca.100PR in Peru

Between September 1, 1932, and May 25. 1933 Colombia and Perú fought an undeclared war over a large portion of territory between the Caquetá and Putumayo rivers, in the western Amazon Forest. The conflict erupted on September 1st when a group of Peruvian citizens occupied the town of Leticia1 as part of a grievance – yet arbitrary -act that, ultimately, led to the Peruvian government support of the illegal seizure, thus prompting the Colombian reaction. This undeclared war lasted -in its active phase- the next eight months and spawned large rearming processes by both sides in order to meet wartime requirements.

After nearly nine months of fighting – the guns went silent on May 25, 1933, thanks to the intervention of the League of Nations intervention. The subsequent signature of a cease-fire between the governments of Peru and Colombia allowed to cool down a conflict that threatened to turn into a declared war between the two countries. While the League of Nations declared its jurisdiction to review the legal aspects of this conflict and to issue its decision regarding the validity of the Salomon-Lozano treaty and, therefore, the parties’ true legal rights over Leticia and the territories between the Putumayo and Caquetá rivers, the pause in operations was considered a most welcomed break by the Cuerpo de Aviación del Perú -CAP- (Peru’s Aviation Corps), as this meant a much-needed rest period for its crews as well as an opportunity to complete the rearming process launched in April 1933 thanks to the approval of the external indebtedness of the state2, which opened the path for the dispatch of purchase commissions to France, Italy, the United Kingdom and the United States.

The CAP entered the hostilities suffering from a chronic deficiency of primary trainers and this, added to the sudden increase in operations, translated into a high rate of accidents that was, by far, the main cause of the reduction of operational capacity in the theatre of operations by April 1933. Learning from the mistakes, one of the main requirements established by the CAP high staff for the re-equipment process was the purchase of basic and intermediate trainers, a requirement that was partially met with the purchase of a batch of six Morane Saulnier M.S.316ET.2 and a similar quantity of Hanriot H.438 from France. The parasol trainers, however, proved to be a bit difficult to master and a number of fatal accidents were recorded. A trio of Curtiss Model 51 Fledgling also joined the training fleet in the summer of 1933 but, despite these acquisitions, the demand for a proper basic training plane remained unsatisfied.

The Caproni Ca.100S.63

Three second-hand Ca.100 powered by the Colombo S.63 engine were allegedly sent to Perú aboard the S.S. Traviata in early June 1934, as a gift from Count Giovanni Caproni to the Peruvian government after the deal between his company and the CAP for the provision of a total of 25 airframes signed early that year. The catch behind the “donation” was that the Caproni trainers were to be used as demonstrators for potential customers in the region, including the Peruvian military aviation, using CAP infrastructure to support these commercial operations.

After their arrival, one of the semi-assembled airframes was fitted with floats at Callao harbor and flown to the nearby seaplane station at Ancón for evaluation. The other airframes, in the meantime, were taken to Las Palmas airfield where they were subject to inspection and tuning in order to begin with the test flights, which were performed by Lt. Bianchi who arrived in the country shortly afterwards. On September 23, 1934, and during a ceremony commemorating another Peruvian aviation anniversary, the aircraft, still in full Regia Aeronáutica livery, were officially presented during an ‘open doors’ festival held at Las Palmas airfield.

The results of the evaluations proved that the Caproni sesquiplane was an easy-to-handle aircraft, but its fragile wooden construction and in-line power plant contradicted the requirements set by the acquisition plan of April 1933, that is, having a wooden structure and radial engine. For these reasons the type was ruled out for acquisition as an instruction aircraft, and the “donated” airplanes were used as liaison and hacks until late 1937 when the Comandancia General de Aeronáutica (General Aeronautics Headquarters, CGA) ordered the transfer of the aircraft under the control of the Liga Nacional de Aviación, a government-sponsored civil aviation school predecessor of the current Escuela de Aviación Civil (Civil Aviation School) with base in Limatambo airfield, in Lima. There, the docile sesquiplanes provided training for dozens of new Peruvian civil pilots. By late 1941, however, accidents, lack of spare parts and the tear and wear on their airframes put an end to the Ca.100S.63 service in Perú.

The Fábrica Nacional de Aviones Caproni Peruana S.A.

In 1936, with the aim of creating a national aviation industry, the Peruvian President General Oscar R. Benavides, with support from Congress, launched an initiative for the creation of a local aviation factory able to satisfy the country’s aircraft requirements for both civilian and military aviation. This proposal was quickly approved by the Executive and Legislative branches of the government and made public knowledge, after which the government initiated the first contacts with the leading foreign companies in the sector looking for adequate proposals. The delicate geopolitical situation in the world, however, caused governments from many countries with leading aviation industries to impose restrictions to such initiatives, as the requirement caught them in the middle of their own rearming processes. The exception was Italy, where the government authorized Societá Aeroplani Caproni S.p.A. to initiate negotiations with the Peruvian government thanks to the excellent relations between both countries at that time. 3

After careful analysis and evaluation, the proposal presented by Aeroplani Caproni was found satisfactory by the Peruvian Supreme Government and, with the consent of the parties, an agreement was celebrated on August 12, 1936 with the signature of the contract by the Head of the Cuerpo Aeronáutico del Perú, Gen. Federico Recavarren, and the representative of Societá per l’Esportazione Aeronáutica, Mr. Quinto Manuel Longo. This agreement, made public by the Supreme Decree published the next day in the Official Journal “El Peruano”, opened the path for the creation of a local aviation industry in the country under the name of Fábrica Nacional de Aviones Caproni Peruana S.A. or FNA for short.

Among others, the text of the agreement included the following:

- The Factory has, as one of its functions, the repair of aircraft airframes and engines of current and future use by the Peruvian military aviation regardless of their country of origin, as well as the fabrication of complete fighter, bomber, trainer, observation and transport structural airframes in accordance with government requirements.

- The required area for the construction of the factory shall be provided, free of charge, by the Peruvian government.

- Societá Aeroplani Caproni commits to complete the factory building in no more than six months after the signature of the contract.

- Societá Aeroplani Caproni commits to complete no less than 35 airframes per year, out of which ten are to be bombers while the rest will be distributed among observation, fighter and training aircraft. The first batch is to be delivered no later than two years after the signature of the contract.

- The Company commits to begin repair work on aircraft currently in service with the Peruvian military aviation within seven months after the signature of the contract.

- The Company agrees to purchase all kinds of machinery required to effectively start its operations.

- The Government agrees to grant the firm a monopoly on repairs and construction of aircraft in the country for a period of ten years.

- The Government accepts to financially compensate the Company for the cost of the factory within a five-year period upon the issuing of the incurred expenses certificated by Aeroplani Caproni S.p.A.

- The Government and the Company agree that the number of workers in the factory, including technical and administrative personnel, will be composed initially of Italian citizens who will be progressively replaced by Peruvian counterparts under the same labour conditions as their predecessors.

- The Government agrees to inform the Company about its material requirements at the beginning of each fiscal period so the factory can trace its production plans accordingly.

- The Government agrees to exempt the Company from customs duties for any aeronautic manufacture-related materials imported from abroad.

- Both parties agree that the costs of repair of aircraft must be previously established by mutual agreement.

- The Company ensures that the final price of the complete aircraft shall not exceed the price of a similar product offered by a reputable foreign firm, otherwise the government will not be obliged to contract with it and be free to do so with any other firm, at will.

- The Company guarantees that materials and machinery used in the manufacture of aircraft will be the same as those approved and used by Italian aviation factories.

- Both parties agree that, in the event of war in Europe, the Peruvian government will have the option to terminate all contracts and therefore any future agreement related to the construction of aircraft, except for repair work and airframe construction contracts in execution at that time which should be completed.

- In the event of war between Perú and other countries, the firm will increase production by a margin of at least one hundred percent; repairs must continue at their usual pace.

- The Company may not export, offer or sell its products to any customer overseas without prior authorization from the Peruvian government.

- The aircraft construction program will be independent from those of repairs and maintenance with the aim of avoiding interference with training and ensuring a steady flow of material to frontline units.

- The Government commits to issue purchase orders for an annual amount of no less than S/. 500,000.004 Soles de Oro as a measure to ensure factory operations. The payment for these operations will be made effective via the National Defense funds.

The construction of the infrastructure for the future factory began in late September after the arrival in Lima, at the beginning of that month, of a contingent of engineers hired by the Societá Aeroplani Caproni S.p.A. to supervise the construction works of the buildings, which were being raised on the large estate located next to Las Palmas airfield.5 German engineer Klaus von Stack was in charge of supervising ongoing work on these grounds.

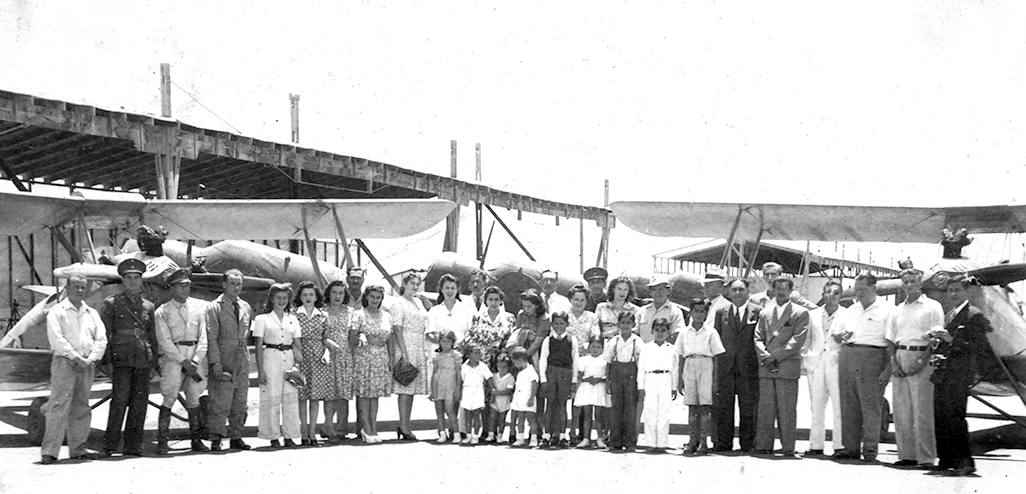

By the spring of 1937 work on the factory infrastructure had a 70% advance, and on May 23, 1937, an Italian delegation of civilian engineers and technicians arrived at Callao harbour aboard the S.S. Orazio, sent by the parent company to form the core of the newly established subsidiary. Upon arrival, the Italian contingent was entertained with an elegant reception organized by local authorities and the numerous Italian expat and immigrant population in Lima. Three days later, the subsidiary began operating, albeit still unofficially.

The Factory

The plant’s infrastructure comprised a total of 16 specialized areas which were divided into the following sections: General mechanics, fuselage repair, welding, metalworking, sheet metal, capping, varnishing, galvanizing, sawing, carpentry and framing, assembly of structures, control room, engine repair and materials test bench. All sections were subdivided into operational areas under the responsibility of one or two specialists. All of these, although different in terms of their size and number of personnel, were fully equipped with machinery and tools in accordance with their various tasks. The Structures Assembly section, however, was the largest, occupying 2000 m2 of total area and had skilled operators. Finally, it is necessary to emphasize that while the average number of employees was 80, when the factory worked at peak capacity, the workforce reached a total of 120 people.

The Caproni Ca.100PR

Among the terms specified in the August 1936 contract, the FNA was obliged to begin the design and production of aircraft for the Peruvian military aviation within a year of the company’s start of operations. Therefore, in strict fulfilment of the agreements, in the summer of 1937 and while construction of the FNA buildings were still underway, the company design department began the work on a basic trainer. Based on the technical requirements established by the CAP, the aircraft fuselage was to be made completely of metal and fitted with a reinforced landing gear, both in order to sustain the rough handling of novice pilots as well as the hardships of operations from unprepared airfields. Finally, the aircraft should be fitted with an engine selected by the Comité Técnico de Adquisiciones (Technical Acquisitions Committee) for its reliability and ease of maintenance: the 125hp Kinner B-5 radial engine.

With these requirements in mind, the FNA engineers designed an airframe that, while having a strong resemblance the Caproni Ca.100 outline – which in fact was an unlicensed copy of the British de Havilland DH.60 Moth – was also a completely new machine. During June 1937, the FNA engineers designed a welded chrome molybdenum steel fuselage structure that was to be covered with duralumin in the forward section and fabric in the rear section. Wings were built out of wood and also covered in fabric. By employing a lighter yet stronger structure, the designers hoped both to increase the resulting aircraft’s useful life as well as performance by reducing the gross weight of the aircraft up to 25% without compromising on power and the basic benefits of the Ca.100 design, such as manoeuvrability and ease of flight. Identified as the Caproni Ca.100PR (for ‘Perú’), the resulting product was to become the first (and only) aircraft ever to be completed and delivered by the FNA during its brief, but meaningful, existence. A total of 12 airframes were initially ordered by the CGA with the aim to use them to replace the Morane Saulnier M.S.316ET.2 trainers.

A couple of interesting details of this trainer were the deletion of the Handley-Page type automatic slats – characteristic of the Ca.100 series – on production machines, as well as the fitting of low-pressure tires on a reinforced landing gear, which allowed operations from poorly prepared fields.

Production of the twelve ordered airframes – identified with construction numbers CP 001 to CP 012 – started in early August 1937. Nevertheless, by the end of September there was substantial progress and the nearly completed airframe was presented to the public in an FNA stand located at the exhibition area of the Primera Conferencia Interamericana de Aviación. During the last days of November, the first completed airframe left the production line, after which a series of evaluation flights began before it could be officially handed over to the CAP. The indigenous trainer was then assigned to the Primera Sección de Instrucción (First Training Section) of the V Escuadrón de Instrucción (Fifth Instruction Squadron, V EI), a training unit attached under the command of the Escuela de Aviación Militar (Military Aviation School, EAM).

In service

Production continued at a rather slow pace during 1938, mainly due to a shortage in manpower caused by the large quantity of projects and assignments carried by the FNA during that year which, aside to the Ca.100PR production, also included the overhaul and modification of the Caproni Ca.111 Ca.114 and Morane Saulnier M.S.316ET.2 fleet, as well as maintenance and repair labour for CAP aircraft fleet. This meant that it was only by the end of March 1939 that the factory delivered the last aircraft.

In the summer of 1939 a reorganization process introduced a number of changes to the CAP units and, consequently, on June 1, 1939, the V EI was disbanded and its units absorbed into the Primer Escuadrón de Instrucción (First Training Squadron, I EI), and the Caproni trainers joined the new unit as part of the first section (basic training) of the I EI, receiving serial numbers I-1-1 to I-1-12, replacing the surviving Morane Saulnier MS.316ET.2 which were, in turn, reassigned to the second section.

Initial impressions of CAP pilots were that the Ca.100PR was a worthy heir to the good features of the original design, with the additional benefit of having a strong structure that could easily withstand the student´s typical mistreatment and rough handling. Additionally, it was found to be safer to handle than the Morane parasol trainers previously assigned to the basic training of students, which had a couple accidents in their record with fatal results. Ground crews were also happy with it, as its engine and structure were easy to maintain and repair. Nevertheless, the intense flying activity typical of any flight school meant that soon a number of Ca.100PR were back at the FNA due to a diverse array of factors ranging from the need for small repairs caused by accidents, to engine tuning and routine inspection on their airframes. The CGA, highly committed in maintaining a high level of operational readiness of the I EA, heavily invested on the provision of spare parts required to keep the training fleet airworthy. Evidence of this is the order issued in October 1940 to the Kinner Motors Inc. – located in Glendale, California – for 12 B-5 engines, at a unit price tag of $1,895.25 US dollars.

The first recorded loss of a Ca.100PR took place on October 10, 1940, when aircraft serial number I-1-10 hit the ground near Villa, about 5 miles southwest of Las Palmas, during a training flight. The crew, composed of Lt. German Flores Chinarro and 3rd year student Cadet Julio Pérez Valverde, sustained serious injuries which led to the death of Lt. Flores a few days later. A year later a second Cachento6 was lost when aircraft serial I-1-7 was heavily damaged after its pilot performed an emergency landing at Las Palmas on November 21, 1941. Given that the seriousness of the damages sustained by the airframe was deemed to be beyond repair by the repair team of the FNA and, after issuing a report to the Ministerio de Aeronáutica7, it was withdrawn from service.

From May 1942, in accordance with the new aircraft identification directives issued by the recently arrived U.S. Military Mission, training aircraft received new serial numbers and identification colours. Accordingly, as the I EI was disbanded and replaced by the 28 Escuadrón de Instrucción (28 Training Squadron, 28 EI), Ca.100PR received new serial numbers and colour scheme, with wings and stabilizers painted yellow while the fuselage was painted blue.

The first batch of 18 Boeing-Stearman A75N1 acquired in 1941 were delivered in February 1942, and these aircraft joined the surviving Ca.100PR in the basic trainer role. By the end of 1943, the first section of the 28 EI still had eight Ca.100PR on inventory but these would soon be reduced to seven when, on December 2, 1st year student Cadet Palma crashed aboard Ca.100PR serial number 28-1-12 on a farm field at San Juan de Miraflores, located about 3 miles southeast of Las Palmas airfield, during a proficiency flight. An engine failure was the chief culprit for this accident leading to the loss of both the aircraft and its unfortunate pilot. Over the course of the following months, the Arsenal de Aeronáutica8 repaired the airframes of several Ca.100PR damaged in accidents and mishaps at the hands of inexperienced student cadets, thus allowing the 28 EI to keep a reasonable number of airworthy trainers in strength.

The CAP took delivery of additional numbers of PT-17 during 1943, just in time to keep basic training operations uninterrupted, as the numbers of Ca.100PR began to dwindle as a consequence of operational incidents which continued to take their toll on the fleet. Finally, in late 1946, the Ministerio de Aeronáutica took the decision to withdraw the remaining airframes from service with the EAM and, after repair and inspection at the Arsenal de Aeronáutica, decided to assign them to the civil aviation, donating the surviving airframes between the Escuela de Aviación Civil (Civil Aviation School, EDACI) and the Aero club in Chiclayo. In civilian hands, the Cachento continued to serve successfully for another decade until the last airworthy airframe was finally retired around 1956. Unfortunately, not a single airframe of this Peruvian historically remarkable aircraft has survived to our days.